Microcrystalline cellulose (MCC) is a widely used substance found in many industries, ranging from food production to pharmaceuticals and cosmetics. Its versatility, non-toxic nature, and stability make it a valuable ingredient in countless products. However, many people may not be familiar with where MCC comes from and how it is produced. In this article, we will explore the origins of microcrystalline cellulose, its production process, and its various applications in the modern world.

What is Microcrystalline Cellulose?

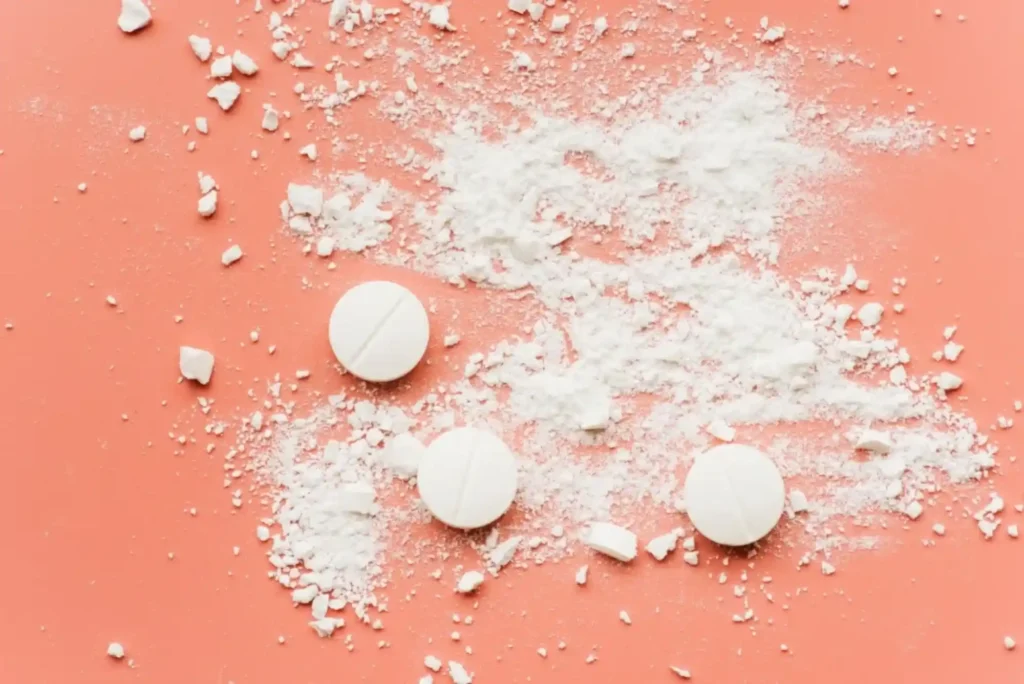

Microcrystalline cellulose is a refined form of cellulose, which is a natural polymer found in the cell walls of plants. As a white, odorless powder, MCC is commonly used as a stabilizer, thickener, and bulking agent in various products. It is a highly purified form of cellulose that has undergone a series of treatments to break down its structure into smaller, more digestible particles. This process allows MCC to retain its essential properties while making it more functional for industrial applications.

MCC differs from other forms of cellulose, such as powdered cellulose, in its texture and crystallinity. The microcrystalline structure of MCC gives it unique properties, including its ability to bind with other substances, absorb moisture, and resist degradation. These characteristics make it an ideal ingredient for a wide range of products.

The Source of Microcrystalline Cellulose

The primary source of microcrystalline cellulose is plant material, specifically cellulose-rich fibers found in wood pulp and cotton. Cellulose is the main structural component of plant cell walls, providing rigidity and strength to the plant. Since cellulose is abundant in nature, it serves as an ideal raw material for producing MCC.

Common Sources of MCC

Wood pulp, which comes from trees, is one of the most common sources of MCC. Trees such as pine, spruce, and fir are typically used in the production of wood pulp. Cotton, another widely used source, is rich in cellulose fibers, making it another common material for MCC production. Other plant-based materials, such as bamboo, flax, and hemp, can also be used to extract cellulose for MCC.

The renewable nature of cellulose makes it an environmentally friendly raw material, as it can be replenished through sustainable forestry practices and agricultural methods.

The Production Process of Microcrystalline Cellulose

The production of microcrystalline cellulose involves several steps to extract and refine cellulose from plant fibers. The first step is to harvest raw materials such as wood pulp or cotton fibers. These materials are then subjected to a chemical treatment process, typically involving an acid or alkali solution, to break down the cellulose fibers.

Hydrolysis Process

The process of hydrolysis is key to producing MCC. During hydrolysis, the cellulose is treated with an acid or enzyme to break it down into smaller, soluble components. This process removes any impurities and non-cellulosic substances, resulting in a purified form of cellulose.

Mechanical Treatment

After the hydrolysis process, the cellulose is subjected to a mechanical treatment to reduce its particle size and create a fine powder. The resulting microcrystalline structure of MCC gives it its unique properties, including its high surface area and ability to bind with other substances. The final product is then purified and dried to remove any remaining moisture, resulting in a stable and ready-to-use form of MCC.

Applications of Microcrystalline Cellulose

Microcrystalline cellulose has a wide range of applications across various industries due to its unique properties. Some of the most common uses of MCC include:

In the Food Industry

MCC is often used in the food industry as a food additive, where it serves as a bulking agent, stabilizer, and texturizer. It is commonly found in processed foods such as baked goods, dairy products, and beverages. MCC helps improve the texture of food products, giving them a smooth and consistent appearance. It also acts as a fat replacer in low-fat or reduced-calorie products, providing a similar texture without adding extra calories.

In addition to its role as a texturizer, MCC is used as a carrier for flavors and nutrients, allowing them to be evenly distributed throughout food products. It is also commonly used in dietary supplements as a filler or binder in tablet and capsule formulations.

In the Pharmaceutical Industry

Microcrystalline cellulose is widely used in the pharmaceutical industry due to its excellent binding and disintegration properties. It is commonly used as a filler and binder in tablets and capsules, helping to hold the ingredients together and ensure proper dosage. MCC also plays a critical role in improving the stability and shelf life of pharmaceutical products.

In addition to its binding properties, MCC is used as a disintegrant in tablets, allowing them to break apart and dissolve more easily in the digestive system. This ensures that the active ingredients are released in a controlled manner, improving the efficacy of the medication.

In Cosmetics and Personal Care Products

MCC is also used in cosmetics and personal care products such as lotions, creams, and shampoos. It acts as a thickening agent, helping to improve the texture and consistency of these products. Additionally, MCC is used as an emulsifier, helping to mix oil and water-based ingredients and prevent separation.

MCC’s ability to absorb moisture and provide a smooth, non-greasy texture makes it a popular ingredient in skincare products. It helps to create a pleasant sensory experience for users while enhancing the performance of the product.

Other Industrial Uses

Beyond food, pharmaceuticals, and cosmetics, MCC is used in a variety of other industrial applications. It is found in paints, adhesives, and coatings, where it helps to improve the texture, stability, and spreadability of the product. MCC is also used in the paper industry, where it is employed as a filler to improve the quality and durability of paper products.

Environmental Impact and Sustainability

One of the key benefits of microcrystalline cellulose is its sustainability. Since MCC is derived from plant-based materials, it is a renewable resource that can be replenished through sustainable forestry practices and agricultural methods. This makes MCC an environmentally friendly alternative to synthetic materials that may have a greater environmental impact.

Sustainable Sourcing of Raw Materials

The production of MCC also benefits from ongoing efforts to reduce waste and improve energy efficiency. Many manufacturers are working to minimize the environmental footprint of MCC production by using renewable energy sources and recycling byproducts from the process.

However, it is important to note that the sourcing of raw materials, such as wood pulp, can have environmental implications if not managed responsibly. Sustainable forestry practices and certification programs, such as the Forest Stewardship Council (FSC), help ensure that the raw materials used in MCC production are sourced in an environmentally responsible manner.

Health and Safety Considerations

Microcrystalline cellulose is generally regarded as safe for consumption and use in various products. It is approved by regulatory bodies such as the U.S. Food and Drug Administration (FDA) and is classified as a Generally Recognized As Safe (GRAS) substance. MCC has been extensively studied for its safety in food and pharmaceutical applications, and no significant health risks have been identified when used within established limits.

Potential Side Effects

While MCC is considered safe for most individuals, it is always important to follow recommended usage guidelines. Excessive consumption of MCC may cause digestive discomfort, such as bloating or gas, although such effects are rare. As with any food or pharmaceutical ingredient, it is essential to consult with a healthcare professional if you have concerns about its use.

Microcrystalline cellulose is a versatile and widely used substance that plays an important role in various industries. Derived from natural plant materials such as wood pulp and cotton, MCC undergoes a detailed production process to create a highly purified and functional product. Its unique properties make it an essential ingredient in food, pharmaceuticals, cosmetics, and other industrial applications.